Selective Non-Catalytic Reduction (SNCR)

Clean Combustion & Energy (CC&E) brings together engineers and technicians who have designed, supplied, installed, and started up eighteen (18) SNCR systems in recent years. These SNCR systems have been installed on a wide variety of boilers; wall fired, opposed wall fired, tangential fired, cyclone, and stokers with typical NOx reductions range from 25-50% depending on boiler design.

Clean Combustion & Energy (CC&E) brings together engineers and technicians who have designed, supplied, installed, and started up eighteen (18) SNCR systems in recent years. These SNCR systems have been installed on a wide variety of boilers; wall fired, opposed wall fired, tangential fired, cyclone, and stokers with typical NOx reductions range from 25-50% depending on boiler design.

Our experience with the SNCR technology includes both urea and aqueous ammonia based systems. Each SNCR system is designed to the specific requirements of the client.

Depending on the boiler operating profile, the SNCR design may contain single or multiple injection zones.

System Design & Supply

The SNCR process is temperature dependent and requires that the SNCR reagent is injected into the optimal temperature zone to achieve the best performance. CC&E starts the SNCR design process with an extensive baseline testing program to collect key operating data and identify the optimal temperature window location for multiple boiler loads across the operating range.

Our testing crew will collect flue gas, O2, CO, NOx, and temperature data across the boiler operating range. Data is collected in the high temperature furnace region data with water-cooled probes, as well as at the furnace exit with multi-point sampling grids.

This baseline data is used to validate CC&E’s full furnace CFD model. The CFD model is essential in determining the optimal quantity and placement of injectors to insure the SNCR reagent is injected into the optimal temperature zone with the correct spray coverage.

CC&E engineers work closely with plant personal to design and specify all components of the SNCR system. After approval of the SNCR engineering specifications, CC&E will begin the fabrication and supply of the SNCR skids, injectors, and various components.

CC&E oversees the skid fabrication, performed by an affiliated company, to maintain quality control. All fabricated equipment is thoroughly inspected and checked for proper operation. The checkout includes a full functionality review of the stand alone PLC system supplied with SNCR system.

CC&E provides installation support and onsite startup to insure a correct and timely installation of the SNCR system. Our engineers and technicians conduct an extensive optimization test program to achieve maximum system performance while minimizing reagent usage to control operating cost. CC&E completes the SNCR system supply with detailed training sessions for both operating and maintenance personnel.

Optimization Testing

The experience CC&E engineers and technicians have with combustion testing and tuning efforts provides us a decisive advantage over other SNCR suppliers. Our proven approach to SNCR tuning guarantees the best possible result for system performance and reagent utilization.

The experience CC&E engineers and technicians have with combustion testing and tuning efforts provides us a decisive advantage over other SNCR suppliers. Our proven approach to SNCR tuning guarantees the best possible result for system performance and reagent utilization.

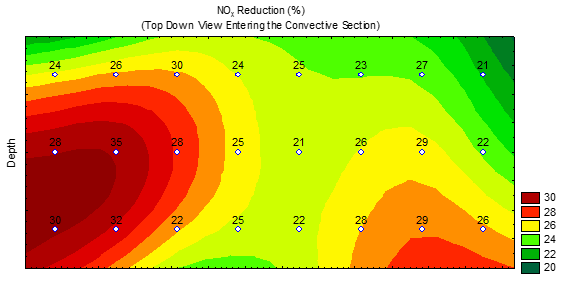

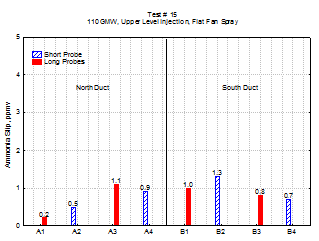

Our staff installs an automated, multi-point sampling grid to measure NOx emissions with and without SNCR injection. The primary objective of the tuning effort is to create a uniform NOx reduction profile across the boiler.

Imbalances in NOx reductions can be an indicator for areas with unreacted NH3 or NH3 slip. High NH3 slip levels in combination with SO3 in the flue gas form ammonium bisulfate (ABS), a sticky compound that leads to backend fouling.

In addition to the multi-point NOx testing, CC&E collects multiple NH3 slip samples for each test condition using EPA CTM-027. Our technicians analyze the samples immediately to provide data for our engineers to make the appropriate adjustments to the reagent injection rate or injector nozzles.

A critical item that CC&E focuses on is reagent utilization. The performance of a SNCR system is not just measured by NOx reductions. Reagent utilization is the main component in determining the operating cost for the SNCR system. Our engineers are always looking to lower reagent usage while maintaining high levels of NOx reduction to provide cost effective NOx control.

Our testing approach can be applied to SNCR systems supplied by CC&E or existing systems supplied by others, as wells as SCR systems. Our staff has supported several SCR OEMs with startup and tuning services.