Combustion CFD Modeling

Computational Fluid Dynamic (CFD) modeling has become the preferred tool for the design of industrial components and processes. CC&E engineers have more than 20 years experience using CFD to tackle one of its most challenging applications: combustion and air pollution.

Computational Fluid Dynamic (CFD) modeling has become the preferred tool for the design of industrial components and processes. CC&E engineers have more than 20 years experience using CFD to tackle one of its most challenging applications: combustion and air pollution.

CC&E engineers specialize in using CFD modeling to address the issues faced by the operators of utility scale boilers and furnaces. CC&E employs state of the art modeling to analyze and design solutions for operational problems, resulting in cost-saving improvements in stack emissions, combustion efficiency and equipment reliability.

Computational modeling is available to solve problems with:

- Inefficient fuel combustion

- NOx & other pollution control equipment

- Heat transfer in process furnaces

- Slag accumulation

- Thermal failure of combustion equipment

- High CO or high LOI emission

- Burner operation issues

- Thermal efficiency issues

- Corrosion of combustion equipment

- Migration to biomass fuels

CC&E’s CFD modeling of combustion processes can accomodate:

CC&E’s CFD modeling of combustion processes can accomodate:

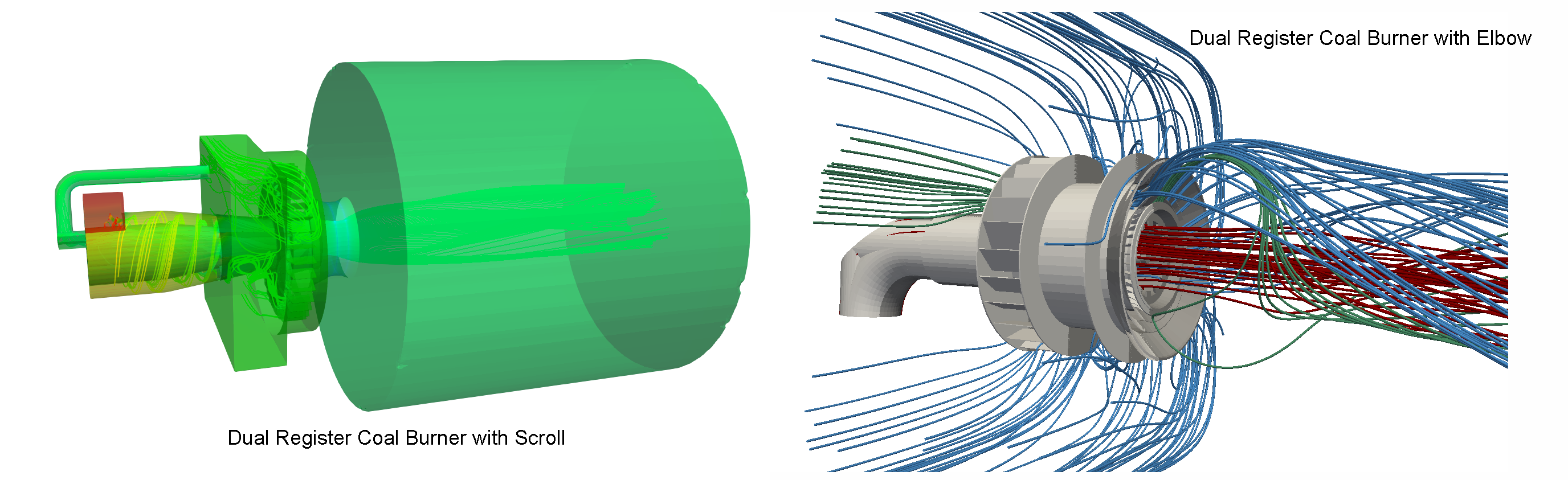

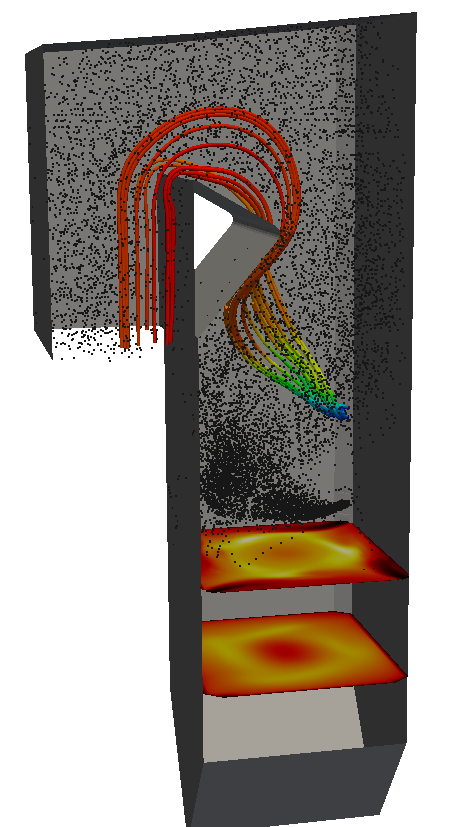

- Complex geometries

- Multiphase gas and particle flows

- Gas, liquid and solid fuel combustion

- High turbulence levels

- Radiation & large temperature gradients

- Complex chemical reaction mechanisms

- Interaction of turbulence and chemistry

- Flow through porous media

Field Testing to Validate CFD

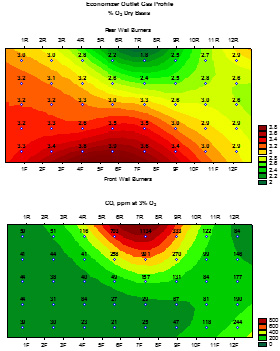

The engineers and technicians at CC&E specialize in testing and optimizing combustion systems and pollution control equipment. This hands on experience with boilers and furnaces contributes to achieving accurate CFD modeling predictions by providing current measurements to which modeling can be compared and tuned.

The engineers and technicians at CC&E specialize in testing and optimizing combustion systems and pollution control equipment. This hands on experience with boilers and furnaces contributes to achieving accurate CFD modeling predictions by providing current measurements to which modeling can be compared and tuned.

CC&E’s typical validation test measurements consist of 24 or more O2, CO, and NOx readings in the furnace and at the furnace exit, plus multiple readings specific to the requirements of the project (NH3, SO3, SO2, temperature, flyash carbon, flyash loading)

CC&E’s detailed data provides the information necessary to correlate real-world emissions to the CFD modeling. This allows CC&E’s engineers to make recommendations based on accurate predictions.

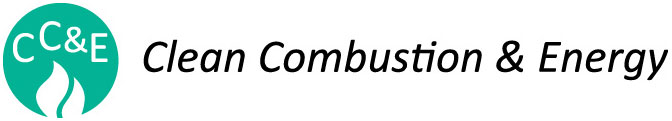

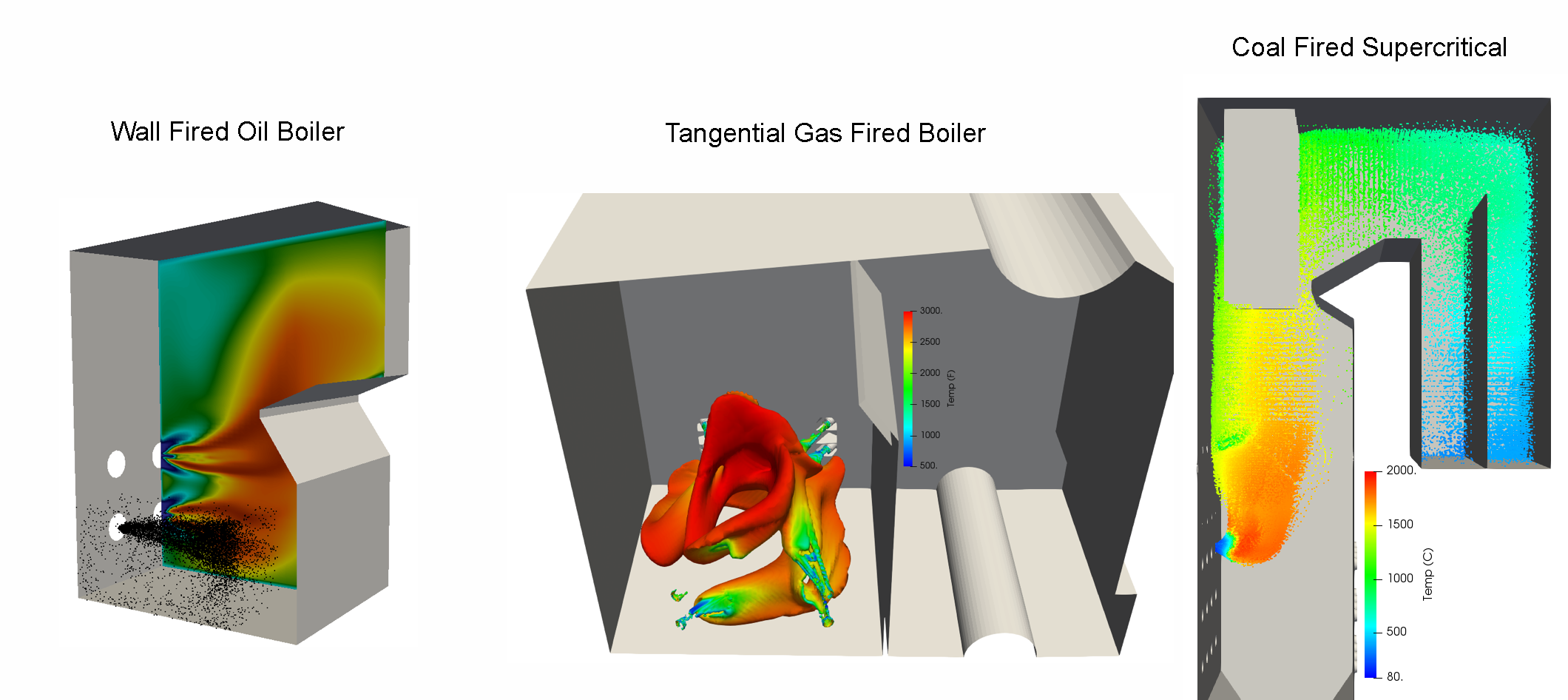

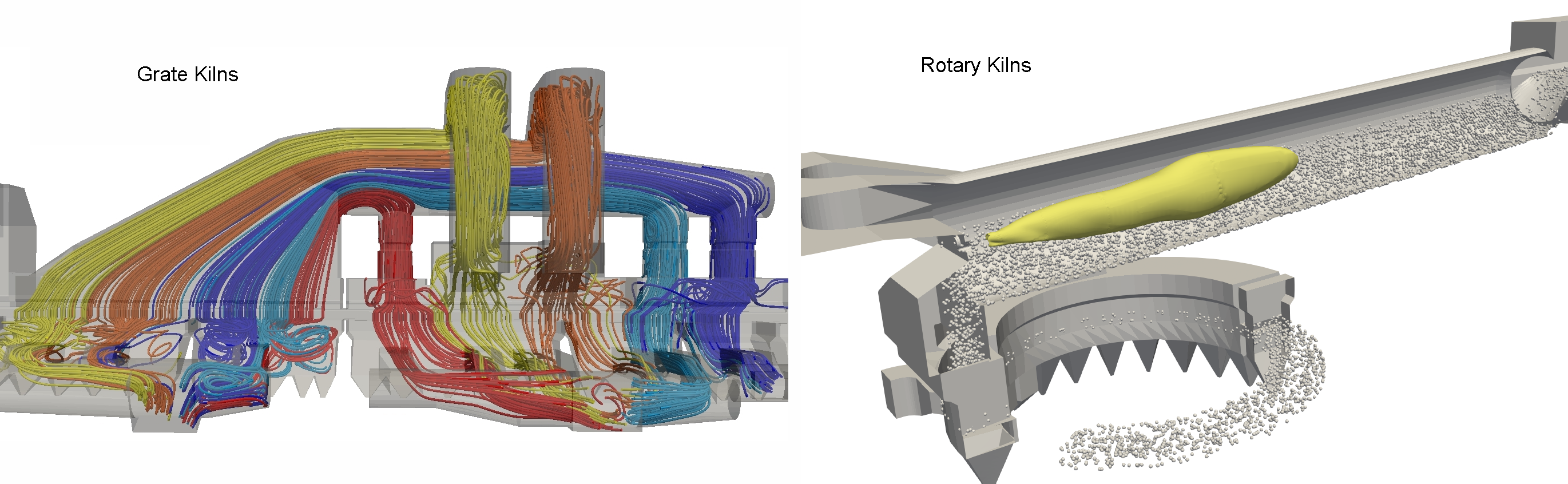

Example CFD of Components and Systems

In addition to CFD of combustion, CC&E can conduct CFD evaluation of a large variety of components and systems.

CFD models of boilers, any type, fuel, or size.

CFD models of material processing kilns.

CFD models of ducts and fans.

CFD models of coal, gas or oil burners.